- Cutting wheel

- Grinding wheel

- grinding head/mounted point

- diamond grinding wheel

- Flap grinding wheel/disc

- Whetstone

- File

- non-woven grinding mop

- Abrasive paper

- Wool product

- Steel wire series

- PVA stone polishing series

- Polishing wax

- Cloth wheel

- Car polishing

- manicure

- Polishing equipment & accessories

- 恒明空压机系列

Polishing Wax

当前位置:首页 > Polishing Wax

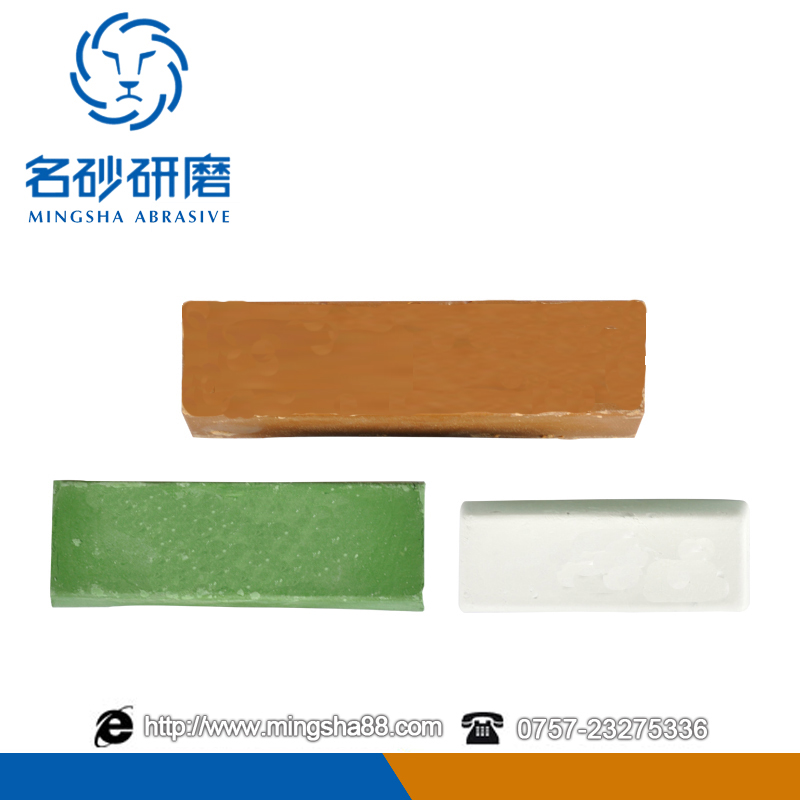

蜡(黄蜡、紫蜡、白蜡、绿蜡)

用途:用于增加金属、非金属抛光亮度

形状:块状

规格型号:可根据客户要求定做

常用的有四种:

(1)白色抛光膏。由硬脂酸、脂肪酸、氧化铝粉、单甘脂、石蜡、羊毛脂等配合而成。主要成分是氧化铝。适用于任何材质的精细抛光。

(2)黄色抛光膏。由硬化油、凡士林、松香、石英粉、氧化铁黄等配合而成。主要成分是长石。适用于金属或非金属的粗抛。

(3)绿色抛光膏。由硬脂酸、单甘脂、蜂蜡、石蜡、羊毛脂、适量氧化铬绿和出光较好的氧化铝粉等配合而成。主要成分是氧化铬绿和氧化铝。适用于任何工件的镜面抛光。

适用范围:采用高档进口材料精制而成,具有很强的切削力,功效快,光泽度高,均匀,表面光泽无磨痕,还有降温,溶解分离等作用。抛光后不同蜡能发出黑色冷光,超白光等亮度,达到超卓镜面,含防锈油脂成分高,可延长产品防锈寿命。

抛光工序分为三步:粗抛、中抛和精抛。要获得最佳性能必须选对用有针对性的抛光蜡。一般情况下为避免适用时混乱分别会用不同的颜色表示不同品种的抛光蜡。不同品种的抛光蜡用处不同

黄色:适合抛光和研磨软金属,如黄铜,铝,铜

白色:适用于研磨黄铜,铝,铜,不锈钢铁,加强表面的光泽度

绿色粉色:适用于研磨不锈钢,铁,铝的精光抛作,达到镜光无暇的8K效果

黑色紫色:适用于切削和磨光钢铁及不锈钢铁上所有刮痕和瑕疵

PolishingWax (yellow wax, purple wax, wax, green wax)

Purpose: to increase the polished metal and nonmetal

Shape: massive

Specifications: can be customized according to customer requirements

There are four commonly used:

(1) white polishing paste. It is made up of stearic acid, fatty acid, aluminum oxide, monoglyceride, paraffin, lanolin and so on. The main component is alumina. Suitable for fine polishing of any material.

(2) yellow polishing paste. From hardened oil, Vaseline, rosin, quartz powder, iron oxide yellow. The main component is feldspar. Suitable for heavy metal or nonmetal.

(3) green polishing paste. It is made up of stearic acid, monoglyceride, beeswax, paraffin wax, lanolin, right amount of chromium oxide green, and better aluminum oxide powder. Chromium oxide green and alumina. Suitable for mirror polishing of any work piece.

Scope of application: the use of high-grade imported materials and refined, with a strong cutting force, the effect of fast, high gloss, uniform, surface gloss without wear marks, as well as cooling, dissolution and separation of the role. After polishing different wax can send a black cold light, ultra white light and other brightness, to achieve a super mirror, with a high composition of rust preventive oil, can extend the product life

The polishing process can be divided into three steps: rough casting, middle polishing and fine polishing. To obtain the best performance, you must select the appropriate polishing wax. In general, in order to avoid confusion in the use of different colors will be different colors of different varieties of polishing wax. Different varieties of polishing wax

Yellow: suitable for polishing and grinding soft metals such as brass, aluminum, copper

White: suitable for grinding brass, aluminum, copper, stainless steel, to enhance the surface gloss

Green Pink: suitable for grinding stainless steel, iron, aluminum, and the naked light, to achieve the effect of mirror light 8K

BlackPurple: suitable for cutting and polishing all scratches and blemishes on steel and stainless steel